Solutions

-

More reliability in normal operations. More flexibility in emergency situations. More certainty in well control.

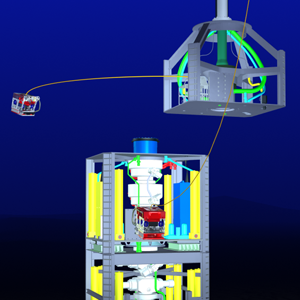

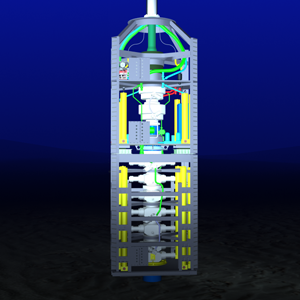

The SafeStack System was designed to allow for multiple access points to the wellbore and equipment control systems, thereby granting greater control of the well. The design also supports the efficient recovery and re-installation of subsea stack components when maintenance and testing are required.

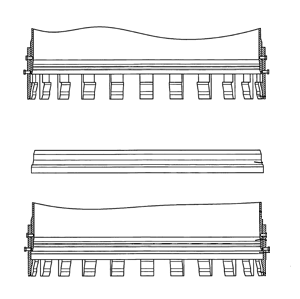

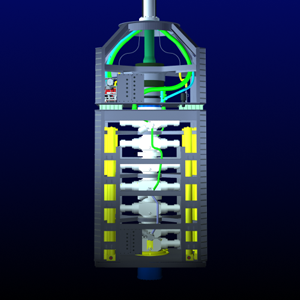

The SafeStack System is a drilling package with a triple modular BOP system. The system is comprised of an RDP (Riser Disconnect Package), a modified LMRP (Lower Marine Riser Package), and a lower BOP stack. The height of the SafeStack three-component system is less than or equal to the overall stack height of standard BOP configurations, yet will contain fewer leak paths.

Rather than introduce new and unproven technology, the SafeStack System utilizes proven and trusted components in various new combinations and configurations. This results in additional well containment/well control possibilities and the opportunity to execute safer and more efficient drilling operations.

View “The SafeStack System” Video

SYSTEM COMPONENTS

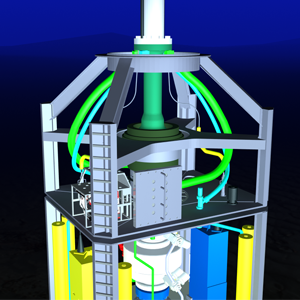

Riser Disconnect Package (RDP)

The RDP is the uppermost modular component and the heart of the SafeStack System. The RDP is attached to the modified LMRP though a proprietary connection system consisting of a flex joint and a connector. In the event of an unplanned LMRP or BOP failure, the RDP disconnects and the necessary equipment is recovered to surface without having to recover the marine drilling riser.

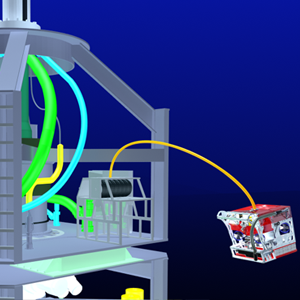

The RDP features a resident work class ROV with the capacity to observe and intervene on all current regulatory required functions of the BOP system.

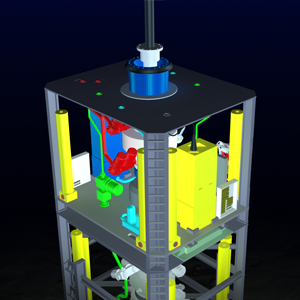

Modified Lower Marine Riser Package (LMRP)

The LMRP contains a majority of the complex functional components and has a higher propensity for failure. Its design has been modified to include an additional connection point above the LMRP. In the event of a failure, the RDP disconnects and the LMRP is efficiently recovered to surface by way of drill pipe. In a blowout situation, the system enables the rapid deployment and landing of emergency re-entry well control equipment such as a capping stack or dome flow cap.

Additional annular design modifications to the LMRP include:

- 15 kspi well bore pressure rating from wellhead to capping stack affixed to top of LMRP

- Large bore bypass lines and valves to provide additional flow path, if required

- Reduced number of flanged connections

- Overall BOP stack height reduction

- Additional valving, controls, and instrumentation to give clear reporting on the BOP’s function

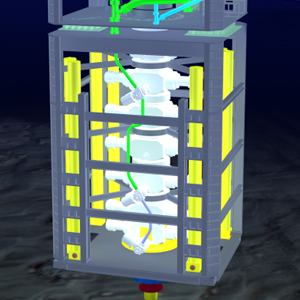

Lower Blow Out Preventer (BOP)

The lower BOP stack has not been modified in the SafeStack system design. The modified LMRP remains able to connect to the lower BOP with a connector and interface hub as currently used today. In the event of a failure, the RDP and LMRP combination disconnects and the BOP is efficiently recovered to surface by way of drill pipe.

-

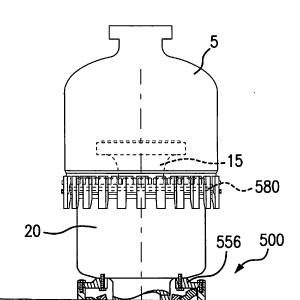

Release Connector/Interface Hub

The patented release connector and interface hub combination provides unprecedented connectivity among the BOP components. The release connector (and interface hub) can be integrated into any component so that it faces either up (connector inverted position) or down.

Latch Flange

SafeStack’s proprietary latch flange can be integrated into its release connector or interface hub, which will allow a capping stack or lightweight containment dome to be installed in an emergency situation.

Lightweight Dome and Latching Mechanism

SafeStack’s patented lightweight dome, incorporating a sturdy latching mechanism, ensures a quick, efficient seal over any part of the modular system.

Resident ROV

SafeStack offers a resident ROV so that a visual eye is always on the stack. The resident ROV is capable of handling many of the functions of the work-class ROV.

-

As was experienced in the Macondo well blowout, a loss of well control can also mean the loss of the rig and all of the well management systems. The ability to contain the hydrocarbon effluent is hampered by the delay experienced in getting clear access to the well bore. Equally, the lack of access to the control systems located on the LMRP causes significant delays in gaining access to the well bore. All the while, resources are expended, effluent is lost, and dispersant is used.

The SafeStack system addresses conventional shortcomings through the addition of both primary and secondary release and connection systems at multiple levels, in every configuration of the BOP and its operating system. For example, through use of SafeStack’s patented inverted release connector system, hydrate formation has been shown to be vastly reduced, if not entirely eliminated. This will allow quick, efficient capping of any wild well.

Should the debris field impact the LMRP during a wild well scenario, the LMRP can be rapidly, safely removed. SafeStack’s multiple, consistent interfaces among the components are critical to the greater effectiveness and efficiency of well control interventions.

Safestack’s tri-modular system also addresses the situation which few have successfully done: the bent BOP scenario. SafeStack’s tri-modular system allows for two solutions to the bent stack:

- install a capping stack, or

- install the SafeStack lightweight dome.

Given the ease in which the first module, the RDP, can be released from the LMRP, the capping stack can be installed as soon as the RDP is released and set aside. However, when it is not possible to set the capping stack, SafeStack’s proprietary lightweight dome can be lowered onto the bent Lower Stack to contain and divert the flow of well effluent. No other system is presently known to be able to effectively control a wild well in the bent BOP stack scenario.

-

SafeStack’s system is both practical and visionary. Not only is it a leap forward for today’s BOP systems, but it also provides a solution to 20 Kpsi and higher systems. SafeStack provides a method of setting the heavier, larger BOP systems with no need to redesign today’s rigs, vessels, or equipment.

Setting the SafeStack System

The SafeStack system’s tri-modular design enables more efficient drilling and production while saving time, safeguarding the environment, and offering unprecedented environmental protection and effluent conservation, whether during normal or emergent operations.

Setting the 20 KPSI and Higher System

Safestack’s method for installing the 20 KPSI and higher systems is simple, efficient, and safe. Not only can it be done more quickly than with a two-component BOP stack, but it can be done without the enormous investment required to place heavier, larger systems. SafeStack paves the way to a safer, more efficient industry, allowing your company’s capital to be spent on production, rather than redesign.